- Indora, Kangra, Himachal Pradesh

- GST NO. : 02AAEPG5118P1ZT

- View Mobile Number

Coatings On Conduit

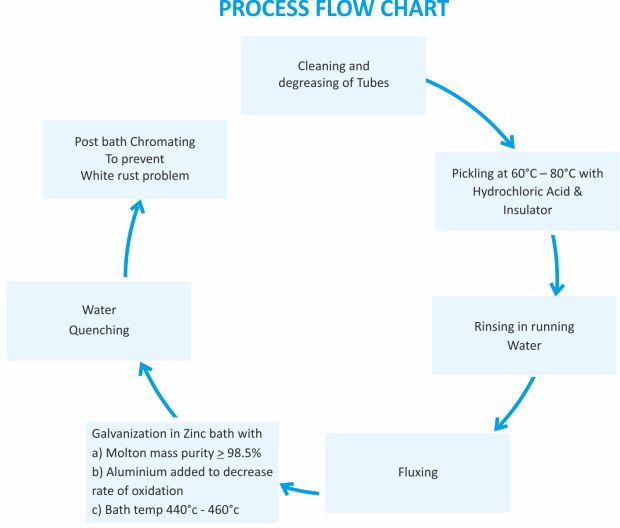

(b) Galvanization Process (for High Protection)

Additional Information-

Mass of Zinc Coating

Mass of Zinc coating shall not be less than 360gm/m2 (50 Micron) as determined from the average. Results of two specimen taken from the opposite ends of the tube selected for testing. This mass of Zinc is measured by any one of the two method described below.

- Mass before and after Galvanization

- By way of magnetic method.

By measuring the thickness of coating with the help of Alcometer the mass of coating in gram per square meter shall then be calculated by multiplying the thickness in mm by a factor 7047.

Contact Us

Sidharth Steel Tubes

Plot 17, Industrial Area Bain Attarian, Tehsil Indora, Indora, Kangra, Himachal Pradesh - 176401, India

Call Us : View Mobile Number